HS-2 Waterra Oil – Water Interface Sensor

Waterra Oil - Water Interface Sensor uses Ultrasonic Technology

The HS-2 Waterra Oil – Water Interface Sensor represent some of the most advanced technology available today for hydrocarbon product layer measurement. These devices utilize sophisticated ultrasonic sensors to help define the product layer. Tests have shown that these sensors are more sensitive in a broader range of hydrocarbon products than conventional optical systems.

Waterra offers these sophisticated sensors in 2 Reel configurations as present below.

Open Reel

Closed Reel

Waterra Words of Wisdom

HS-2 Waterra Oil-Water Interface Sensor Features

- auto shut-off

- rugged modular construction

- powered by 4 AA batteries

- membrane ON/OFF switch

- extremely low power consumption

- sensor’s probe is 5/8″ diameter 316 stainless steel

- probe snaps into a probe holder on the side of the reel when not in use

- ultrasonic transducer used to detect hydrocarbons and a conductivity sensor to detect water

- dog bone polyethylene tape cross-section design prevents adherence to wet surfaces such as well casings

- metric tapes are graduated to the nearest millimetre

- imperial tapes are graduated to the nearest 1/100 of a foot

Polyethylene is the standard graduated well tape option.

The Waterra Oil-Water Interface Sensor comes with standard Polyethlene coated tape in metric or footric graduations. Polyethylene coated tapes are PFAS free.

As an option, Kynar coated tapes which are tougher and more chemically inert are available by special order. But please note that Kynar is a fluorocarbon (PVDF) so if PFOA or PFAS are concerns at your site, you may want to stick with the polyethylene coated tapes.

Kynar is:

- extremely non-reactive with many different substances

- extremely pure, strong, and able to resist heat, bases, acids, and solvents

- very resistant to ultraviolet rays

- Kynar coated tapes can be special ordered but check with us for availability and timing.

The HS-2 line of Oil-Water Interface Sensors use tough, plastic reels to protect the stainless steel tape from damage and dirt while the tape is stored on the reel. They are made from black polyethylene and lightweight so they are very portable.

The HS-2 Open Reel is available with tapes in metric units of 30, 50, and 100 meters or 100 or 250 feet. Polyethylene coated tapes are standard but Kynar coated tapes can be special ordered.

The HS-2 line of Oil-Water Interface Sensors use tough, plastic reels to protect the stainless steel tape from damage and dirt while the tape is stored on the reel. They are made from black polyethylene and their lightweight and slim profile make them very portable.

The HS-2 Closed Reel is only available with either a 30 meter or a 100 foot Polyethylene coated tapes.

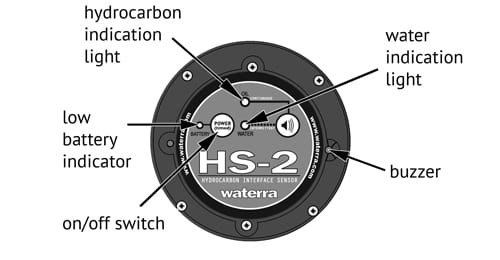

- membrane ON/OFF switchwith an automatic power saving feature that will turn the unit off after three minutes

- water indication light LED display that illuminates when water is detected

- hydrocarbon indication light LED display that illuminates when hydrocarbons are detected

- loudest buzzer available was chosen for these sensors to ensure that the units could be heard in noisy environments.

- low battery indication light

- battery pack is located on underside of faceplate

All interface meters operate with a two sensor (switch) system. The first sensor, either optical or ultrasonic, is responsible for detecting liquids, regardless of the nature of the liquid. These sensors cannot distinguish between hydrocarbon and water, so a second sensor is necessary in order to make this determination. All interface meters use a simple conductivity sensor to determine if the liquid detected by the first sensor is water (conductive) or hydrocarbon (non-conductive).

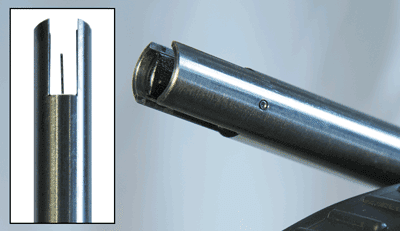

The Competition

Optical based sensors usually use blunt steel posts as their conductivity electrode and are mounted adjacent to the optical prism. This shape of electrode (located immediately adjacent to the optical crystal) gets coated with viscous product and stays coated for a long time, until the probe is lowered far enough into the water where the hydro-static pressure is strong enough to squeeze the coating product up the probe’s body. Additionally, having a probe body that extends below the location of the electrodes increases the amount of product that must move before the electrode can “see” the water.

The HS-2 Difference

The biggest difference between our conductivity sensor and the competition’s is the shape of our electrodes. Our sensor uses a thin stainless steel wire which is protected within the tip of the probe. The thin wire is a shape that viscous hydrocarbon liquids have a hard time holding onto and so this electrode clears very quickly as the probe passes from the LNAPL layer into the water below. You can see the configuration of our probe tip in the image above.