How to Develop Monitoring Wells

Use Waterra Pumps or EcoBailers

How to Develop Monitoring Wells as well as surging and cleaning them out is easily solved using Waterra equipment. Many ground water sampling programs have a protocol for well development prior to sampling. Essentially this is to “clean out” the fines which may be mobilized into future samples giving erroneous results. Surging water into and out of the formation helps accomplish this. At times sediment can build up in the bottom of a well creating a silted monitoring well. Waterra has two options to deal which these situations but by far and away the Waterra Pump is the better of the two options presented below.

Option 1

Developing, surging and silted wells with a Waterra Pump

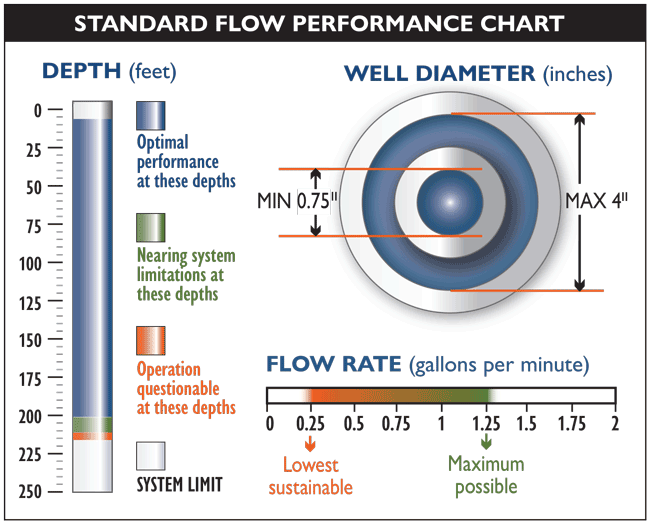

The Waterra Pump, especially using a Waterra Surge Block, is a great well development, surge and silted well tool for 2 inch (5 cm) monitoring wells and certain 4 inch (10 cm) wells. The system is capable of developing wells sometimes up to 200 feet (61 m) deep.

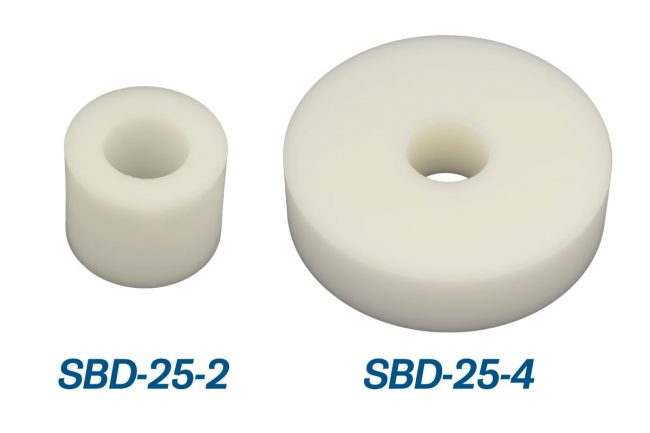

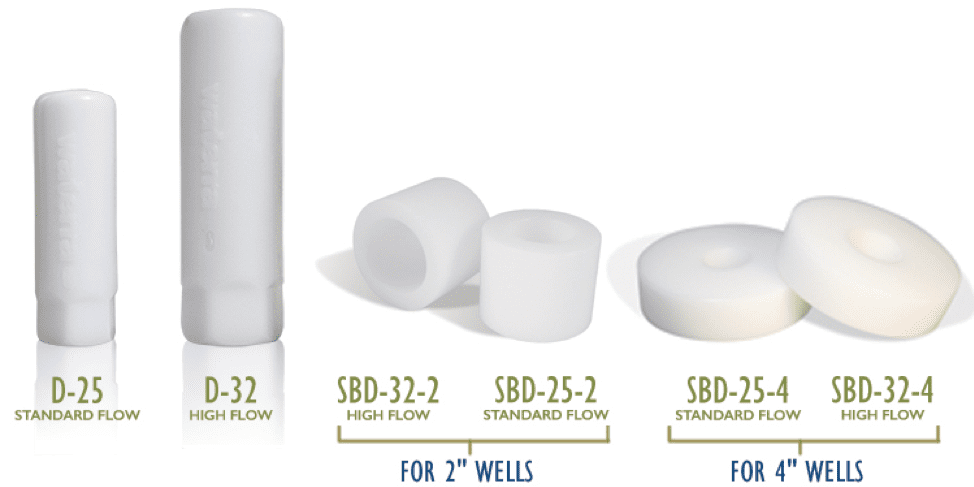

The Waterra Pump system produces excellent well development, surging and clean out results because of the combination of simultaneous pumping and gentle well surging. Fines drawn into the well or “stirred up” will be pumped out. A Surge Block which is a plastic ring or doughnut that fits over certain Waterra Foot Valves, increases its diameter. This greatly reduces the annular gap between the well screen and the Foot Valve – Surge Block combo thereby enhancing the surging effect.

You will need four components:

Waterra Foot Valve + Waterra Surge Block + Waterra Tubing + Tubing Actuator.

Waterra offers four configurations which are presented vertically in the table below.

| 2 Inch Wells | 2 Inch Wells | 4 Inch Wells | 4 Inch Wells | |

|---|---|---|---|---|

| Most Common | >139ft (39m) | <30 ft (9m) | Most Common | |

| Foot Valve | D-25 | D-32 | D-25 | D-32 |

| Surge Block | SBD-25 | SBD-32 | SBD-25-4 | SBD-32-4 |

| Tubing | Standard | High Flow | Standard | High Flow |

| Tubing Actuator | Lever Pump, Hydrolift, Power Pack | Lever Pump, Hydrolift, Power Pack | Lever Pump, Hydrolift, Power Pack | Lever Pump, Hydrolift, Power Pack |

As always, a Waterra technician is available to help you choose an appropriate configuration for your application.

- Press or bang a Waterra Surge Block about halfway along a Waterra Foot Valve

- Thread the Foot Valve Surge – Block Combo securely onto matching Waterra Tubing

- Insert the tubing, valve first, into the well.

- Feed the tubing down the well to the screened interval

- Cut off the tubing leaving about 6 feet (2m) above the top of the well

- Affix the Waterra Tubing Actuator to the well head

- Connect the tubing to the actuating arm and also the fixed discharge point on the actuator

- Begin pumping by turning on the Tubing Actuator to oscillate the tubing – foot valve assembly up and down in the monitoring well

- Continue pumping at your desired rate until the flow is clear or meets your turbidity goal

- As above, except make sure you know how much silt you need to clean out and make sure you have enough tubing for the pump to operate properly and reach the bottom of the well.

- Position the valve/surge block combo close to the water-sediment interface.

- Extend more tubing down well as the interface moves down the well.

Waterra Words of Wisdom

- For longer screened intervals one should develop sections several sections keeping in mind the stroke length is 4 to 6 inches.

- Wells can be developed without the Surge Blocks but not as effectively

- The advantage of the mechanized drive systems is the fact that whilst purging or developing, the field person is available to do other tasks.

- Leave a loop of about 6 feet of tubing between the actuator arm attachment point and the fixed discharge point and allow extra tubing if you are working deeper and deeper

-

This product has multiple variants. The options may be chosen on the product page

Waterra Hydrolift Pump – Tubing Actuator

$USD 2,850.00 – $USD 2,950.00 -

This product has multiple variants. The options may be chosen on the product page

Waterra Surge Blocks – Standard Flow

$USD 11.85 – $USD 20.38

Option 2

Developing wells with an EcoBailer

Bailers are not the ideal tool to develop or surge a well but if you don’t, or can’t, use a Waterra Pump, a bailer might help.

Ecobailers are suitable for most contaminated environments and are available in four sizes from 0.5 inch (13 mm) to 3.3 inch (84 mm) outside diameters and in PVC and polyethylene. There are also weighted versions. These disposable bailers are low cost and eliminate cross contamination. They are individually packaged; each with a bailer emptying spout.

- Choose largest diameter bailer for your well eg 1.5inch OD bailer for 2 inch well

- Lower bailer on cord to screened interval

- Pull up 10 feet (3m) rapidly to create low pressure zone in the well and a rush of inflow

- Repeat numerous times until turbidity goal is achieved

- Occasionally bring the bailer to surface and dump to remove turbid water from the well

Waterra Words of Wisdom

- Not the greatest way to develop a well.

- Well development with a bailer is labour intensive

- Bailing can leave a lot of sediment in the well

- A Waterra Pump with a Surge Block is much more effective

-

This product has multiple variants. The options may be chosen on the product page

Clear PVC eco Bailer Groundwater Sampler

$USD 85.44 – $USD 178.45